Industrial engineers develop efficient systems which integrate workers, machinery, materials, energy and information. They can also design products or services. Industrial engineers may work at an office or a production facility, like a warehouse or manufacturing plant.

Industrial Engineer Entry Level in Texas

Your job as an industrial engineer is to ensure that production processes run smoothly. You will be responsible for analyzing problems, troubleshooting and implementing improvements to increase efficiency. You can also train technicians to use the equipment and systems you designed.

You will have different duties depending on which company you are working for and what they need. Some manufacturers may require you to create a system for the handling of hazardous waste. Some require you to design a system of monitoring and controlling raw materials.

As manufacturers are constantly looking for ways of cutting costs and increasing efficiency, you may be working on projects that reduce waste in the production process. It could be reducing inventory, increasing the efficiency and effectiveness of machinery, or identifying wasteful practices.

You may work for an electronics or computer company. These jobs tend to be full-time. Employment is expected grow by 10% within the next 10 years.

Manufacturing Engineering Jobs in Texas

Start your career in industrial engineering by taking a job at a company that makes heavy machinery, or energy equipment. Many plant managers are looking for candidates who have this kind of experience.

During your tenure at the factory, you'll be expected to take part in seminars and training programs. These training opportunities will help you become a more productive member of the team, and you might be assigned to perform specialized research that helps you refine your skills as an industrial engineer.

Eastman Manufacturing Engineer

You may be offered a job as an industrial engineering at Eastman Chemical Mcallen in Texas if your skills match the requirements. This is a fast-paced and rewarding position that offers the opportunity to work at a leading technology and energy company.

As an industrial engineers, you'll be responsible for the implementation and maintenance of engineered labor standard in distribution centres across the nation. You will be an integral part of the team of industrial engineers, responsible for presenting engineering labor standards and distributing them to the associates of these facilities.

FAQ

What skills do production planners need?

Production planners must be flexible, organized, and able handle multiple tasks. You must also be able to communicate effectively with clients and colleagues.

How can manufacturing avoid production bottlenecks

You can avoid bottlenecks in production by making sure that everything runs smoothly throughout the production cycle, from the moment you receive an order to the moment the product is shipped.

This includes both quality control and capacity planning.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma is a management method that helps to improve quality and reduce waste.

It is focused on creating consistency and eliminating variation in your work.

Is it possible to automate certain parts of manufacturing

Yes! Automation has been around since ancient times. The Egyptians created the wheel thousands years ago. Today, robots assist in the assembly of lines.

In fact, there are several applications of robotics in manufacturing today. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

There are many other examples of how manufacturing could benefit from automation. 3D printing makes it possible to produce custom products in a matter of days or weeks.

What does manufacturing mean?

Manufacturing Industries are companies that manufacture products. The people who buy these products are called consumers. This is accomplished by using a variety of processes, including production, distribution and retailing. They manufacture goods from raw materials using machines and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

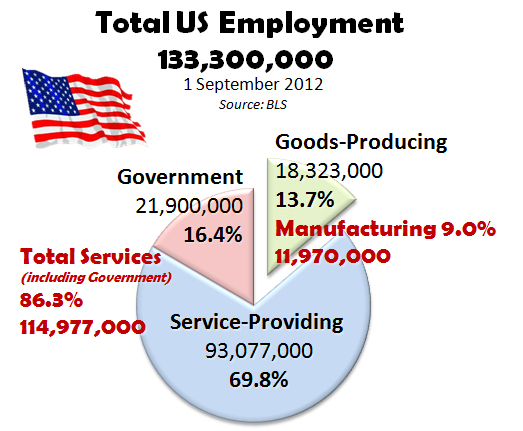

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use 5S to Increase Productivity in Manufacturing

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation developed the 5S method in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

This method has the basic goal of standardizing production processes to make them repeatable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. These actions allow workers to perform their job more efficiently, knowing what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step involves a different action which leads to increased efficiency. By sorting, for example, you make it easy to find the items later. Once you have placed items in an ordered fashion, you will put them together. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. Make sure everything is correctly labeled when you label your containers.

This requires employees to critically evaluate how they work. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. They must learn new skills and techniques in order to implement the 5S system.

The 5S method not only increases efficiency but also boosts morale and teamwork. They will feel motivated to strive for higher levels of efficiency once they start to see results.