Across industries, supply chain disruptions have caused long-term productivity deficits and economic losses. It has been shown that companies' failures to manage risks proactively have contributed to the disruptions.

In the face of growing internationalization, the defence industry has been affected by this trend. There may be a shortage of certain technologies, such high-quality carbon-fiber and advanced semiconductors. This can lead both to increased dependence and oligopolistic behavior. There is also an increased risk of dual products. These products can pose safety and reliability concerns.

In the face of globalization, the security of critical minerals is critical to the development of modern industrial systems. Some minerals are located in economically less developed countries and could be vulnerable to political instability. Under different circumstances the optimal global allocation of crucial minerals will change. China is a critical node in the global critical minerals value chain, but the industry is highly dependent on other nations. Instead of concentrating resources in one country, it is vital that governments create a global critical minerals allocation network that includes multiple countries.

Discussions about the European Union's defense technology and industrial bases (DTIB), have been ongoing. The European Commission launched the European Defence Agency, (EDA), to create a framework that will allow for a new European defense industry. This new approach will see a number of improvements in the EU's military industry. A limited number of non EU companies can supply certain technologies. Monopoly and oligopoly structures will be used in the EU's defense industry. It will also be easier to purchase certain raw materials from non EU companies. This will allow for the development of a new type sourcing strategy called bundled volumes.

It is becoming more important to develop a secure and resilient supply network. There are a number of strategies that can be implemented to mitigate the risk of supply chain disruptions. One strategy is to implement a formal risk management plan. The formal risk management approach can help the supply chain thrive rather than survive. It should include both internal as well as external key stakeholders such suppliers, investors, government officials, and other governments. Management of the supply chain should be in line with global supply-chain dynamics.

Security of the 99m/99mtc supply network is another critical policy issue. The policy approach adopted by the High-Level Group on Medical Radioisotopes - HLG-MR ensures long-term security for the supply of radioisotopes. This included a review of 99 Mo/99mtc global supply chains, an analysis of economic impacts of the supply and a policy approach.

The HLG-MR identified two main areas of vulnerability that should be addressed in order to enhance the security of the 99 Mo/99m supply chain. These areas include monopolistic behavior, political conflicts, and foreign capital. These factors can create significant risks and increase prices. HLGMR identified key steps needed to address these vulnerabilities in its policy approach.

FAQ

What is production management?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. It is important to have everything ready and planned before you start shooting. It should also contain information on achieving the best results on set. This information includes locations, crew details and equipment requirements.

First, you need to plan what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

Once you have found the right vehicle, you can think about adding accessories. Do you need people sitting in the front seats? You might also need someone to help you get around the back. You may want to change the interior's color from black or white. These questions will help to determine the style and feel of your car. Another thing you can do is think about what type of shots are desired. Do you want to film close-ups, or wider angles? Maybe you want to show the engine and the steering wheel. All of these things will help you identify the exact style of car you want to film.

Once you have established all the details, you can create a schedule. A schedule will tell you when you need to start shooting and when you need to finish. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. Everyone will know what they need and when. You can also make sure to book extra staff in advance if you have to hire them. It is not worth hiring someone who won’t show up because you didn’t tell him.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects only take one or two days, while others may last weeks. When creating your schedule, be aware of whether you need more shots per day. Shooting multiple takes over the same location will increase costs and take longer to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another important aspect of production planning. It is important to set a realistic budget so you can work within your budget. Keep in mind that you can always reduce your budget if you face unexpected difficulties. It is important to not overestimate how much you will spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

How can excess manufacturing production be reduced?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the time needed to manage inventory. By doing this, we could free up resources for other productive tasks.

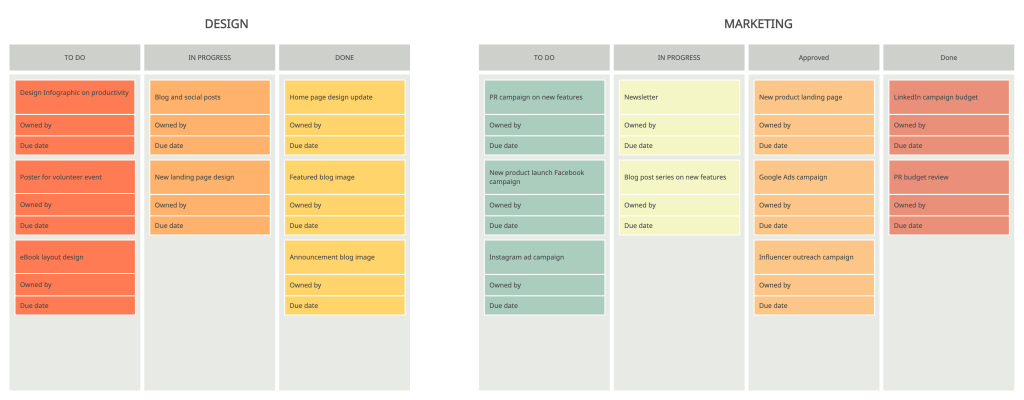

You can do this by adopting a Kanban method. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents an individual priority level.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. It is possible to keep a task in the beginning stages until it gets to the end.

This allows work to move forward and ensures that no work is missed. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This data allows them adjust their workflow based upon real-time data.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing is about eliminating waste from all stages of the production process. Waste includes anything that does not add value to the product. These are some of the most common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What are the responsibilities for a manufacturing manager

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They should also be aware of any problems within the company and act accordingly.

They must also be able to communicate with sales and marketing departments.

They should also be aware of the latest trends in their industry and be able to use this information to help improve productivity and efficiency.

Is automation important in manufacturing?

Not only are service providers and manufacturers important, but so is automation. It allows them provide faster and more efficient services. It helps them to lower costs by reducing human errors, and improving productivity.

What are the four types of manufacturing?

Manufacturing is the process that transforms raw materials into useful products. It can involve many activities like designing, manufacturing, testing packaging, shipping, selling and servicing.

Why is logistics important for manufacturing?

Logistics are essential to any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics plays a significant role in reducing cost and increasing efficiency.

What skills should a production planner have?

Production planners must be flexible, organized, and able handle multiple tasks. You must also be able to communicate effectively with clients and colleagues.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Lean manufacturing can be found in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing is based on five principles:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. To increase their competitiveness, many businesses have turned to lean manufacturing. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

The principles of lean manufacturing can be applied in almost any area of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. Continuous Improvement involves continuous improvement of processes.