The job of a logistics coordinator involves ensuring that goods are in the right place at the right time and arrive in the most efficient and cost-effective way possible. You will ensure that your customers receive their goods on time. Our article provides more information on logistics. In this article, you'll learn more about the roles and responsibilities of inventory analysts, customer service specialists, and supply-chain managers. Listed below are some of the top jobs that you can find in logistics.

Logistics coordinator

Monster has thousands upon thousands of job openings for logistic coordinators. This type of job requires a lot of hands-on training. Candidates with little to no experience are generally expected to take up the training from an apprenticeship or internship, but they can also have previous industry experience. You may be interested in a job as logistics coordinator if you have previous experience.

Customer service specialist

A customer service specialist is responsible for the management and delivery of customer service. They maintain contact with customers, coordinate inland transport, and address customer concerns and complaints. They also manage customer relationships and coordinate appointments. As a customer support specialist, you will also coordinate all necessary documents and documentation to ensure timely and affordable delivery.

Inventory analyst

An Inventory Analyst manages inventory productivity and maintains service level. Their primary responsibilities include the overall order fulfillment for TSC Feed programs, as well as managing the day-to-day activities of inventory replenishment. They manage inventory levels for their respective product categories to support assortment and merchandise planning. They collect data and analyze trends to plan article-site replenishment at stores. They may also help with marketing and promotion activities. They often analyze sales data and create new strategies to improve business efficiency.

Supply chain manager

The supply chain manager manages the flow of goods and materials from suppliers to customers and manufacturers. The role requires a wide range of skills, and a bachelor's degree is typically required. Many employers prefer candidates who have a master's in business administration. There are various ways to qualify for a supply chain manager job. This career field is available to learn more. Consider getting an associate's in business administration if you are interested in a career in supply chain management.

Freight agent

While you're creating your job description, make sure to include a section on your cargo and freight agent responsibilities. Potential applicants will be able to see the main responsibilities for this job in the job description. Make sure to use strong action verbs in your description to get the attention of qualified applicants. A job description should include a list of the qualifications required to fill the position.

FAQ

Why automate your warehouse

Modern warehouses are increasingly dependent on automation. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses must adapt quickly to meet changing customer needs. To do so, they must invest heavily in technology. Automating warehouses has many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

This makes workers more productive

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Quality products delivered on time

-

Human error can be eliminated

-

Helps ensure compliance with regulations

How can I find out more about manufacturing?

Practical experience is the best way of learning about manufacturing. However, if that's not possible, you can always read books or watch educational videos.

Why is logistics important in manufacturing

Logistics are essential to any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics are also important in reducing costs and improving efficiency.

How can manufacturing excess production be decreased?

Better inventory management is key to reducing excess production. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. We could use these resources to do other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban board is a visual display used to track work in progress. Work items are moved through various states to reach their destination in a Kanban system. Each state represents a different priority level.

When work is completed, it can be transferred to the next stage. If a task is still in its beginning stages, it will continue to be so until it reaches the end.

This helps to keep work moving forward while ensuring that no work is left behind. With a Kanban board, managers can see exactly how much work is being done at any given moment. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing is about eliminating waste from all stages of the production process. Waste includes anything that does not add value to the product. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What is the job of a manufacturer manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They should be aware of any issues within the company and respond accordingly.

They must also be able to communicate with sales and marketing departments.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

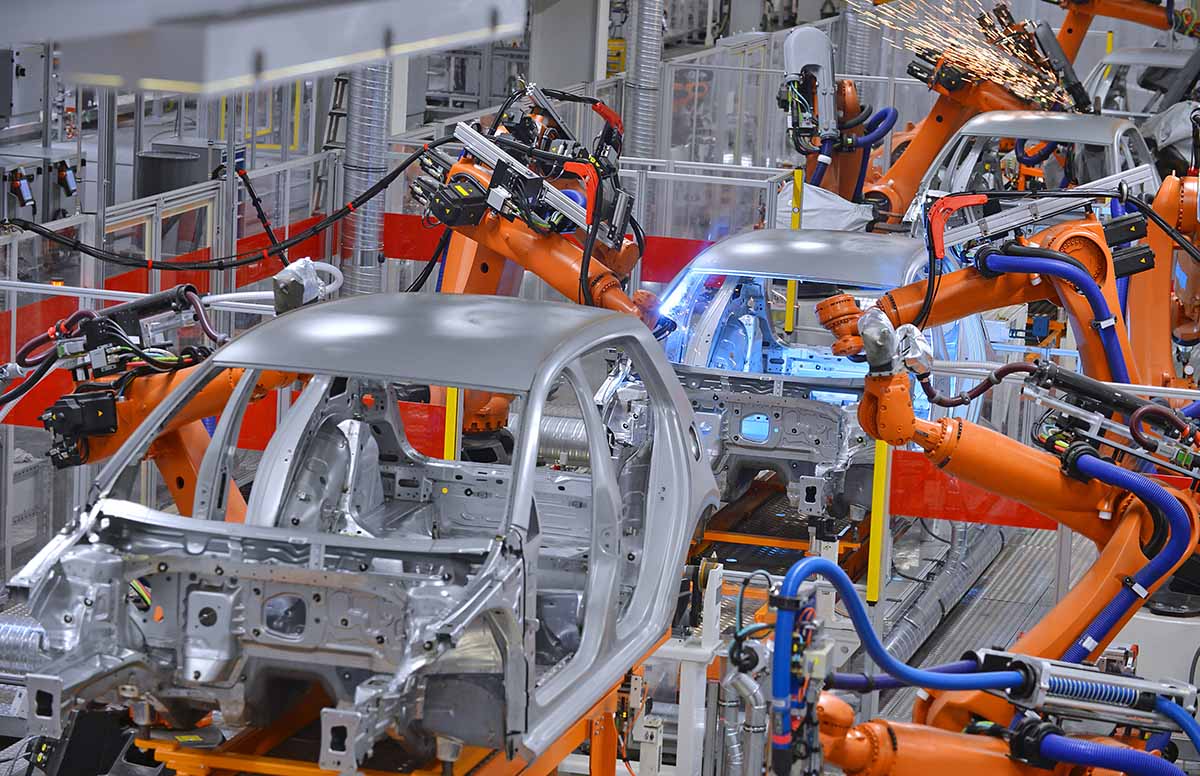

What is the difference between manufacturing and logistics

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics includes all aspects related to supply chain management, such as procurement, distribution planning, inventory control and transportation. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

What are the products and services of logistics?

Logistics are the activities involved in moving goods from point A to point B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma aims to reduce variation in the production's mean value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

The first step toward implementing Six Sigma is understanding how variability works in your business. Once you have this understanding, you will need to identify sources and causes of variation. These variations can also be classified as random or systematic. Random variations happen when people make errors; systematic variations are caused externally. If you make widgets and some of them end up on the assembly line, then those are considered random variations. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you have identified the problem, you can design solutions. That solution might involve changing the way you do things or redesigning the process altogether. To verify that the changes have worked, you need to test them again. If they don’t work, you’ll need to go back and rework the plan.