Industrial engineers design efficient systems that integrate workers, machines, materials, information and energy to make a product or provide a service. They may work in an office or in a production setting, such as a manufacturing facility or warehouse.

Industrial Engineer Entry Level in Texas

As an industrial engineer, you will be responsible for ensuring that production processes are running smoothly. You'll be responsible to analyze problems, troubleshoot issues and implement changes in order to improve efficiency. You can also train technicians to use the equipment and systems you designed.

Your job duties vary depending on the type of company you work for and what their needs are. You might be required by certain manufacturers to develop a way of handling hazardous waste. Some manufacturers require that you develop a method for controlling and monitoring the flow of raw material.

As manufacturers are constantly looking for ways of cutting costs and increasing efficiency, you may be working on projects that reduce waste in the production process. It could be reducing inventory, increasing the efficiency and effectiveness of machinery, or identifying wasteful practices.

You could work for a manufacturer of transportation equipment, or an electronics and computer firm. These are typically full-time positions, with employment expected to grow 10% over the next ten years.

Manufacturing Engineering Jobs in Texas

For a start, you could work in a facility that makes energy or heavy machinery. This is a good way to gain experience in industrial engineering. Many plant managers will look for candidates that have such experience.

You will be required to attend training seminars and programs during your stay at the plant. You will be able to become a better member of the team by participating in these training programs. You may also be asked to conduct specialized research, which helps you improve your skills as an Industrial Engineer.

Eastman Company Manufacturing Engineer

You could be offered the position of industrial engineer by Eastman Chemical, in Mcallen (Texas). It is a rewarding, fast-paced role that allows you to work in a technology and energy company.

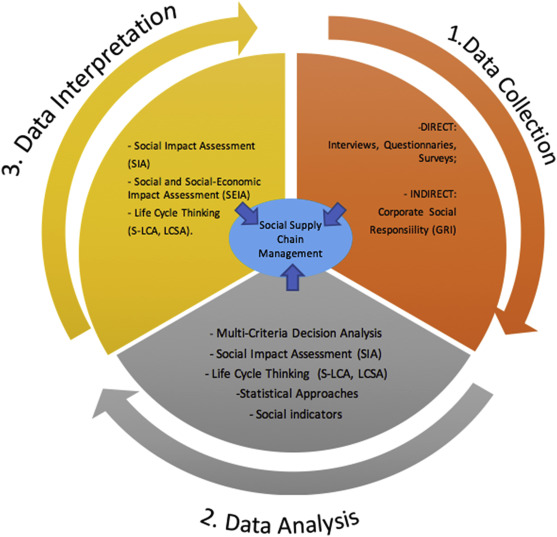

You will be an integral part of the industrial engineering team, responsible for implementing and maintaining engineered work standards in distribution centers throughout the country. You will be a key part of the industrial engineering team, responsible for presenting and providing engineering labor standards to associates at these facilities, assisting in the development of training methods and materials, facilitating change management activities as needed and conducting regular data collection and analysis.

FAQ

What is meant by manufacturing industries?

Manufacturing Industries are businesses that produce products for sale. Consumers are those who purchase these products. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. They create goods from raw materials, using machines and various other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What is the job of a manufacturer manager?

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They should be alert for any potential problems in the company and react accordingly.

They must also be able to communicate with sales and marketing departments.

They should also be aware of the latest trends in their industry and be able to use this information to help improve productivity and efficiency.

How can manufacturing prevent production bottlenecks?

To avoid production bottlenecks, ensure that all processes run smoothly from the moment you receive your order to the time the product ships.

This includes both quality control and capacity planning.

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It's all about eliminating variation and creating consistency in work.

What are the main products of logistics?

Logistics refers to the movement of goods from one place to another.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

What are the responsibilities of a logistic manager?

Logistics managers make sure all goods are delivered on schedule and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should also ensure enough stock is available to meet demand.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands for "Sort", 'Set In Order", 'Standardize', & Separate>. Toyota Motor Corporation invented the 5S strategy in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. Workers can be more productive by knowing what to expect.

Implementing 5S requires five steps. These are Sort, Set In Order, Standardize. Separate. And Store. Each step requires a different action, which increases efficiency. Sorting things makes it easier to find them later. When you arrange items, you place them together. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. Labeling your containers will ensure that everything is correctly labeled.

Employees must be able to critically examine their work practices. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. In order to use the 5S system effectively, they must be able to learn new skills.

The 5S method not only increases efficiency but also boosts morale and teamwork. They feel more motivated to work towards achieving greater efficiency as they see the results.