What is Manufacturing? Manufacturing is the process of creating goods. It employs labor, machines and chemicals to produce products and services. Manufacturing is part the secondary sector of an economy. It employs both manual labor and smart labor to create products. We'll be looking at some of its benefits. Let us consider the process and the benefits of manufacturing. This information can be applied to your business once you have mastered it.

Manufacturing is a subsector.

A sub-sector of the economy, manufacturing is responsible for creating goods or services. To complete manufacturing processes, it requires labor, equipment, tools, and capital. These processes may involve biological or chemical processing. In essence, manufacturing is the essence of the secondary sector of the economy. While manufacturing is important for many different economic sectors, it also has its own unique benefits. Here are some of these advantages.

A strong and vibrant manufacturing industry is key to the U.S.'s economy. Many economists see manufacturing as a business that is primarily focused on consumers, while others see it as a wealth-producing sector. Manufacturing jobs are essential to the economy as they create middle-class jobs and boost overall wealth. As a result, manufacturing creates jobs, spurs innovation, and boosts the economy.

It adds value

Activities that affect the shape or quality of a product in the manufacturing industry are known as value-adding. Non-value-added activities include cleaning equipment, getting material, lining up equipment, sorting items for pick-up order, printing paperwork, and searching for locations. The manufacturing process can be improved by automating non-value-added activities. Here are some examples for activities that could be automated:

Increasing productivity. Automation and computer technology can be used to increase productivity and lower costs. The United States federal law supports the manufacturing process. This includes large-scale production and physical transformation. Manufacturing has been a key component of many industries' success. Many companies have achieved great success because they are able to produce large quantities. Manufacturing is an important part of our economy, and should be studied carefully.

It is manual labour.

"Manual Labour" refers to the physical work that humans do. This is different from the work performed by machines or animals. Manual labour is the act of physically working with your hands or other parts of your body. This has been the main method of physical labor for most of human history. These are just a few examples of manual labor. 1. Agriculture: Handwork is the most widespread method of farming. It's often anchored in crop fields.

There are many reasons why manual labour is more common than unskilled labor. The application of intelligence is possible in almost any work, from artisanal skill in craft production to logic in applied science. Many workers start their careers without having any specific skills, despite all these benefits. Education has become an increasingly important part of modern life, but not everyone is able to have a broad range of experiences. Some jobs require workers to do certain tasks, but not all.

It uses smart technology

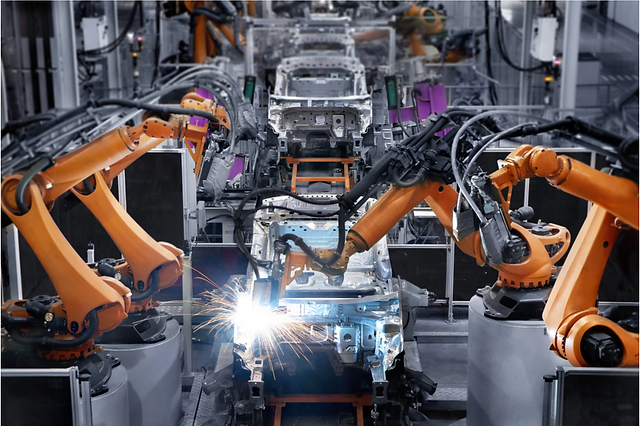

Smart manufacturing is the incorporation of information technology within manufacturing. It increases adaptability, makes use of internet-connected machinery, and optimizes production. It is a collaboration between workers and machines that uses data analytics to improve production margins and profit margins. Smart factories use highly automated systems, interoperable control, and connected sensors. They can react quickly to changes in demand and improve production and quality. Smart manufacturing is not restricted to any one industry or process.

Artificial intelligence allows factories to detect problems and schedule maintenance before it becomes critical. These advanced technologies are able to monitor and respond quickly to supply chain changes, which reduces downtime. Smart factory technologies allow for automation of certain processes. This allows engineers to focus on more complex tasks. Small businesses won't be able afford to invest in smart factories because of their high upfront cost. These technologies are important, but they are an integral part of manufacturing operations.

FAQ

Why is logistics important in manufacturing

Logistics is an integral part of every business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

What skills should a production planner have?

You must be flexible and organized to become a productive production planner. You must also be able to communicate effectively with clients and colleagues.

How does manufacturing avoid bottlenecks in production?

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning for capacity requirements as well as quality control measures.

Continuous improvement techniques such Six Sigma are the best method to accomplish this.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It focuses on eliminating variation and creating consistency in your work.

Why should you automate your warehouse?

Modern warehouses have become more dependent on automation. Increased demand for efficient and faster delivery has resulted in a rise in e-commerce.

Warehouses have to be flexible to meet changing requirements. They must invest heavily in technology to do this. Automation warehouses can bring many benefits. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety is boosted

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

It makes workers more efficient

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Reduces downtime and improves uptime

-

You can be sure that high-quality products will arrive on time

-

Removing human error

-

It helps ensure compliance with regulations

How does a Production Planner differ from a Project Manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. Forecasting and identifying production capacity are two key elements to this process.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

What is production planning?

Production Planning refers to the development of a plan for every aspect of production. This document aims to ensure that everything is planned and ready when you are ready to shoot. This document should include information about how to achieve the best results on-set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to decide what you want. You may have decided where to shoot or even specific locations you want to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

Once you have found the right vehicle, you can think about adding accessories. Are you looking for people to sit in the front seats? Perhaps you have someone who needs to be able to walk around the back of your car. Maybe you want to change the interior color from black to white? These questions can help you decide the right look for your car. The type of shots that you are looking for is another thing to consider. Will you be filming close-ups or wide angles? Maybe you want the engine or the steering wheels to be shown. These details will help identify the exact car you wish to film.

Once you have all the information, you are ready to create a plan. You will know when you should start and when you should finish shooting. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. So everyone is clear about what they need to do. If you need to hire extra staff, you can make sure you book them in advance. There is no point in hiring someone who won't turn up because you didn't let him know.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects take only a few days while others can last several weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiple takes at the same place will result in higher costs and longer completion times. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Another important aspect of production planning is setting budgets. Setting a realistic budget is essential as it will allow you to work within your means. It is possible to reduce the budget at any time if you experience unexpected problems. However, you shouldn't overestimate the amount of money you will spend. Underestimating the cost will result in less money after you have paid for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was created in Japan by Taiichi Ohno during the 1970s and 80s. He received the Toyota Production System award (TPS), from Kanji Toyoda, founder of TPS. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Lean manufacturing is based on five principles:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. To increase their competitiveness, many businesses have turned to lean manufacturing. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

It can be applied to any aspect of an organisation. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three types of lean manufacturing.

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. If a part is required to be repaired on the assembly line, it should not be scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement involves continuous improvement of processes and people as well as tools.