Supply Chain Management Review will provide you with the most current trends in supply-chain management. The magazine, which is based out of the U.S. since 2010, covers topics such as the role information technology plays in business and the changing natures of business models. The magazine offers a detailed look into the industry, which is especially relevant to large supply chain companies.

Supply chain management's final stage is finished with manufacturing

Supply chain management is a complicated process that involves five key elements. They include planning, sourcing raw ingredients, manufacturing, delivery and return, and logistics. To avoid costly bottlenecks companies need to be competent in all these areas. Because perishable goods need to be delivered on time, manufacturing is critical.

Reverse logistics

A company's bottom line is greatly affected by reverse logistics management. This service allows businesses to utilize existing infrastructure to reduce costs, increase efficiency and improve their profitability. Reverse logistics can improve a company’s image by enabling it to employ sustainable business practices. Reverse logistics comes with its own set of challenges.

Flexible model

Businesses can use a flexible supply network to meet customer demand when there is high and low demand. It relies on part segmentation, accurate stocking algorithms, and flexible planning, which includes incorporating automation on factory floors. For example, Staples, which manufactures writing utensils, anticipates a surge in demand during the back-to-school season and stocks up on supplies throughout the year.

Agile model

A review of the Agile model for supply chain management can be a great way to help organizations make substantial changes and ensure that your supply chain is responsive to new developments. While significant delays can result from changes such as the loss a manufacturing partner or logistical blocks, an agile supply chain can resolve these problems quickly. The model gives stakeholders visibility which allows them to continuously improve their supply chain process. It allows organizations to outsource particular supply chain segments, leading to lower costs. It helps companies to anticipate shortages and decrease overstock inventories.

Model of fast-chain

This fast-chain model of supply chain management emphasizes speed, responsiveness, and is best suited for companies that frequently change product lines and compete for the same customers. This model is known for efficient inventory management and maximising the use of production equipment. This model is most suitable for businesses producing trendy products with short life cycles. Businesses that are looking to bring products to market quickly will also benefit from this model.

Management of supply chains with ethics

Companies have made ethics in supply chain management a priority because it affects business performance. The issue affects more than factories and workers: environmental, social, and labor issues are common problems faced by supply chain companies. A variety of initiatives are underway by companies to ensure ethical supply chains.

FAQ

How can excess manufacturing production be reduced?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. This could help us free up our time for other productive tasks.

You can do this by adopting a Kanban method. A Kanban Board is a visual display that tracks work progress. A Kanban system allows work items to move through several states before reaching their final destination. Each state represents a different priority.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This helps to keep work moving forward while ensuring that no work is left behind. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This data allows them adjust their workflow based upon real-time data.

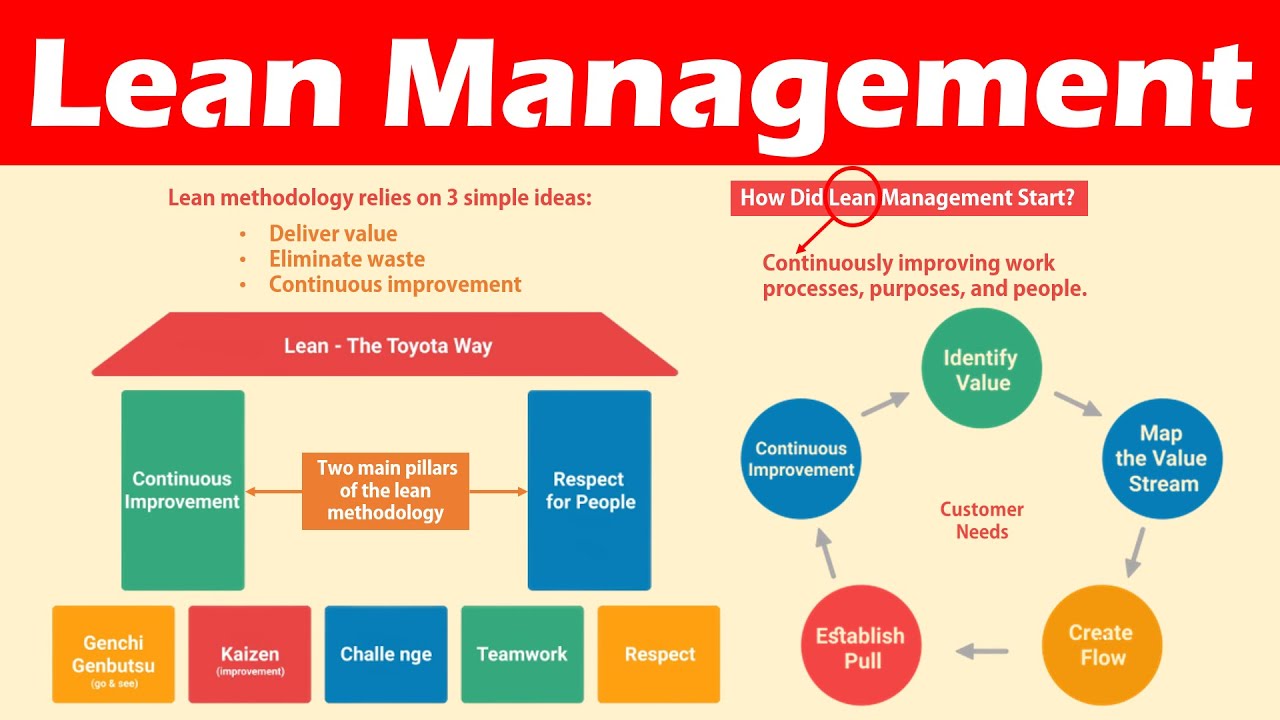

Lean manufacturing is another option to control inventory levels. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Waste includes anything that does not add value to the product. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Exceed materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document will ensure everything is in order and ready to go when you need it. You should also have information to ensure the best possible results on set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

First, you need to plan what you want to film. You may have decided where to shoot or even specific locations you want to use. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. For example, you might decide that you need a car but don't know exactly what model you want. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you have chosen the right car, you will be able to begin thinking about accessories. Are you looking for people to sit in the front seats? Or maybe you just need someone to push the car around. Maybe you'd like to change the interior from black to a white color. These questions will help determine the look and feel you want for your car. You can also think about the type of shots you want to get. Are you going to be shooting close-ups? Or wide angles? Maybe the engine or steering wheel is what you are looking to film. These factors will help you determine which car style you want to film.

Once you've determined the above, it is time to start creating a calendar. You will know when you should start and when you should finish shooting. You will need to know when you have to be there, what time you have to leave and when your return home. This way, everyone knows what they need to do and when. You can also make sure to book extra staff in advance if you have to hire them. There is no point in hiring someone who won't turn up because you didn't let him know.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects take only a few days while others can last several weeks. It is important to consider whether you require more than one photo per day when you create your schedule. Shooting multiple takes over the same location will increase costs and take longer to complete. If you aren't sure whether you need multiple shots, it is best to take fewer photos than you would like.

Another important aspect of production planning is setting budgets. Setting a realistic budget is essential as it will allow you to work within your means. You can always lower the budget if you encounter unexpected problems. It is important to not overestimate how much you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

What is the job of a manufacturer manager?

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should be aware of any issues within the company and respond accordingly.

They should also know how to communicate with other departments such as sales and marketing.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma's main objective is to reduce variations from the production average. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If you notice a large deviation, then it is time to fix it.

The first step toward implementing Six Sigma is understanding how variability works in your business. Once you understand this, you can then identify the causes of variation. You'll also want to determine whether these variations are random or systematic. Random variations are caused by human errors. Systematic variations can be caused by outside factors. You could consider random variations if some widgets fall off the assembly lines. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you've identified the problem areas you need to find solutions. That solution might involve changing the way you do things or redesigning the process altogether. Test them again once you've implemented the changes. If they fail, you can go back to the drawing board to come up with a different plan.