Toyota Production System, originally called Just-in-Time production was an integrated sociotechnical and technological system used to eliminate waste from processes and improve them. It's designed to optimize manufacturing, logistics and customer interaction. It encourages continuous improvement and employee growth. It is the foundation of Lean Manufacturing. Toyota Production System has been applied to many manufacturing facilities in the United States and overseas.

SakichiToyoda, founder of Toyota was the one who developed Toyota Production System. He analyzed every phase of the company's production and eliminated any unnecessary parts. The result was a 20% reduction in the build time. Toyota could also produce a vehicle in half of the time as GM. Toyota was however on the verge to go bankrupt in the 1950s.

Taiichi Ohno, a Toyota executive, observed the shelves-stocking process in a supermarket in the middle of the 1940s. He discovered that Just in Time methods in vehicle production could make it more efficient. He was a co-founder of the Toyota Production System, which was developed between 1948 and 1975 by Eiji Toyoda.

Toyota Production System was developed to eliminate wastefulness and inconsistency. Kaizen, a Japanese concept for continuous improvement, was the foundation of the system. The Toyota Production System is constantly improved to meet the needs of the company. It fosters learning in the company. It uses simple but efficient low-tech tools, combined with advanced production methods. It also utilizes innovative information technology as well unique social/management techniques.

Six core principles form the foundation of Toyota Production System. This system has been modified by many companies, including Boeing and Porsche. These companies reengineered processes in order to copy Toyota's production systems.

Toyota Production System includes activities for team building. These activities include weekly local leader safety rounds, which evaluate the performance of staff with key safety initiatives. All team members are encouraged and encouraged to share their ideas and seek out ways to improve. This has influenced the culture of the company.

Jidoka, another concept, refers automating processes with human touch. Jidoka encourages workers to check their work and stop production when they find problems. Jidoka stresses the importance of correcting mistakes and not ignoring them.

The Toyota Production System also employs visual control. This makes it possible to see work instructions on the factory floor. This makes it easy for workers to follow the instructions. Poka-yoke devices are also used by the company to ensure that quality standards are met. These devices can also be used to verify the identification of a red rabbit.

The Toyota Production System is not only applicable to manufacturing plants, but also health care. It can be used in improving patient satisfaction. It can be used in critical care and the operating rooms.

It is possible to improve patient satisfaction as well as health care delivery by using the Toyota Production System. In 2003, an EPA case study reported that Toyota's efforts in waste reduction had caught the EPA’s attention. This resulted in a partnership with many companies, including the St. Bernard Project which employs military veterans.

FAQ

What does manufacturing industry mean?

Manufacturing Industries are businesses that produce products for sale. The people who buy these products are called consumers. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They create goods from raw materials, using machines and various other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

What's the difference between Production Planning & Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. Forecasting demand is one way to do this.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

What is the role of a manager in manufacturing?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They should be alert for any potential problems in the company and react accordingly.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

How can manufacturing avoid production bottlenecks

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes both quality control and capacity planning.

Continuous improvement techniques such Six Sigma are the best method to accomplish this.

Six Sigma is a management method that helps to improve quality and reduce waste.

It seeks to eliminate variation and create consistency in your work.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

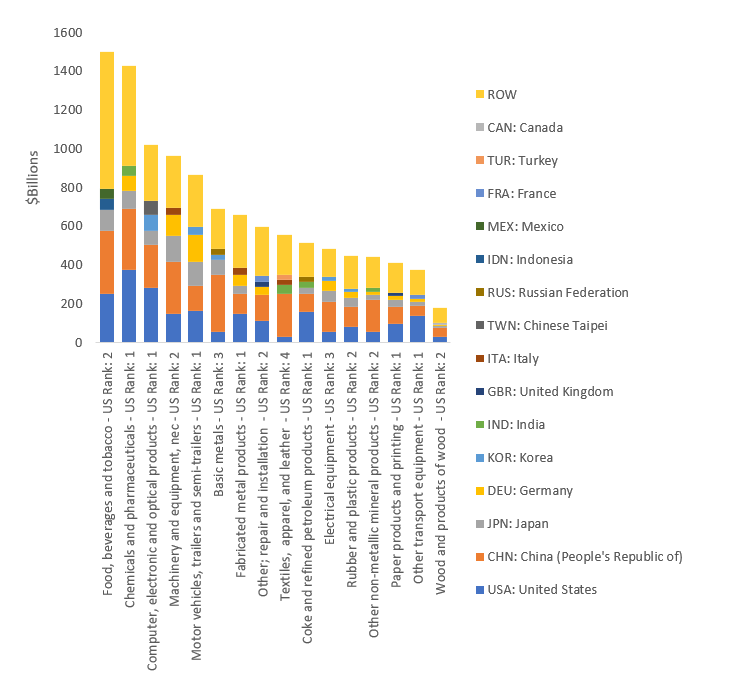

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department, Tokyo, Japan, developed it in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma aims to reduce variation in the production's mean value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you understand this, you can then identify the causes of variation. This will allow you to decide if these variations are random and systematic. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. If you make widgets and some of them end up on the assembly line, then those are considered random variations. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

After identifying the problem areas, you will need to devise solutions. This could mean changing your approach or redesigning the entire process. You should then test the changes again after they have been implemented. If they don't work, you will need to go back to the drawing boards and create a new plan.