Several factors have caused a massive chip shortage in recent years. Manufacturing and transport problems are two of the main reasons for the chip shortage. Many disasters have resulted in the closing of chip plant facilities. This has affected consumer electronics such as gaming consoles and data centers. However, there are several efforts being made by the Chinese government to promote semiconductor manufacturing in the country. The government has even introduced an investment fund to help chip makers.

As a result of this effort, China's chip production has seen tremendous progress over the past few years. According to IC Insights by 2025, China's chip production is expected to increase by 19.4%. The industry still has a ways to go before reaching its former levels. Despite these advances, the number of domestic chip companies is still limited. Many of these companies do not yet have their own independent business.

Huawei, Oppo and Midea are some of China's most well-known chip manufacturers. Chinese companies are also increasing their market share in mobile processors. These companies are also developing their own chips to expand their chip manufacturing capabilities. This has made them more competitive in their industry.

China is rapidly becoming a key chip manufacturing center, but there are still some limitations. For example, Chinese companies do not yet have enough resources to mass produce high-end microchips. These chips are used to make smartphones, tablets, and servers. The country is also not yet able to produce the raw materials necessary for chip manufacturing. These include neon, tantalum and enriched isotopes. These raw materials are refined through chemical processes.

The Chinese government wants to reduce dependence on imported chips. China will produce 70% of its chips in China by 2025, according to the country. But this will take many years. China currently has 32 registered chips companies. Many more are still awaiting IPOs. The government actively markets its industrial policies. It hopes to encourage chip-producing companies to increase production, which is a challenging task considering the scarce resources.

The US semiconductor industry is experiencing an unprecedented shortage in tech talent. Washington recently adopted new rules that make it more difficult for Americans to support chip manufacturing.

TSMC (one of the biggest chipmakers in the globe) has not announced any plans for a European plant. But, it has not ruled building an older-generation European chip plant. The company has also partnered with European automakers to purchase less-advanced chips. The idea was largely rejected by European automakers. Adding a plant in Europe would add to the supply chain, which means chips would have to be shipped back to Asia for back-end processing. This could increase the chip's life expectancy by several years.

According to a report by the US Commerce Department, the chip shortage will become bad in 2021. This has led to long delays for consumers. The shortage has also affected transportation, healthcare, and gaming consoles. The government's investment in reshoring chip manufacturing will create hundreds of thousands of new jobs in the US and help to ensure a more resilient supply chain.

FAQ

What is production plan?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. It is important to have everything ready and planned before you start shooting. You should also have information to ensure the best possible results on set. This includes information on shooting times, locations, cast lists and crew details.

It is important to first outline the type of film you would like to make. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

Once you have found the right vehicle, you can think about adding accessories. Do you have people who need to be seated in the front seat? Or maybe you just need someone to push the car around. You might want to change your interior color from black and white. These questions will help to determine the style and feel of your car. You can also think about the type of shots you want to get. Are you going to be shooting close-ups? Or wide angles? Maybe you want the engine or the steering wheels to be shown. These factors will help you determine which car style you want to film.

Once you have all the information, you are ready to create a plan. You can use a schedule to determine when and where you need it to be shot. A schedule for each day will detail when you should arrive at the location and when you need leave. This way, everyone knows what they need to do and when. Book extra staff ahead of time if you need them. There is no point in hiring someone who won't turn up because you didn't let him know.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects are quick and easy, while others take weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiple shots at the same location can increase costs and make it more difficult to complete. If you are unsure if you need multiple takes, it is better to err on the side of caution and shoot fewer takes rather than risk wasting money.

Another important aspect of production planning is setting budgets. Setting a realistic budget is essential as it will allow you to work within your means. If you have to reduce your budget due to unexpected circumstances, you can always lower it later. It is important to not overestimate how much you will spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Production planning can be a complex process. However, once you know how everything works together it will become easier to plan future projects.

Why automate your warehouse

Modern warehouses have become more dependent on automation. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses must be able to quickly adapt to changing demands. They must invest heavily in technology to do this. The benefits of automating warehouses are numerous. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Allows companies scale more easily

-

Makes workers more efficient

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

It reduces downtime, and increases uptime

-

Quality products delivered on time

-

Eliminates human error

-

It ensures compliance with regulations

What is the responsibility of a production planner?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. They also ensure that the product/service meets the client’s needs.

How can efficiency in manufacturing be improved?

The first step is to determine the key factors that impact production time. We must then find ways that we can improve these factors. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you've identified them all, find solutions to each one.

What skills are required to be a production manager?

You must be flexible and organized to become a productive production planner. It is also important to be able communicate with colleagues and clients.

What is the difference between a production planner and a project manager?

The difference between a product planner and project manager is that a planer is typically the one who organizes and plans the entire project. A production planner, however, is mostly involved in the planning stages.

What does warehouse mean?

A warehouse or storage facility is where goods are stored before they are sold. It can be indoors or out. In some cases, it may be a combination of both.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

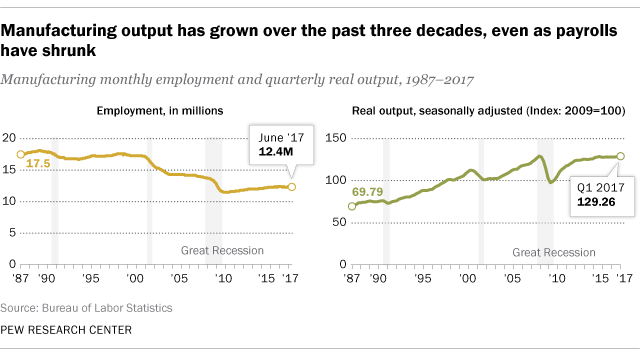

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

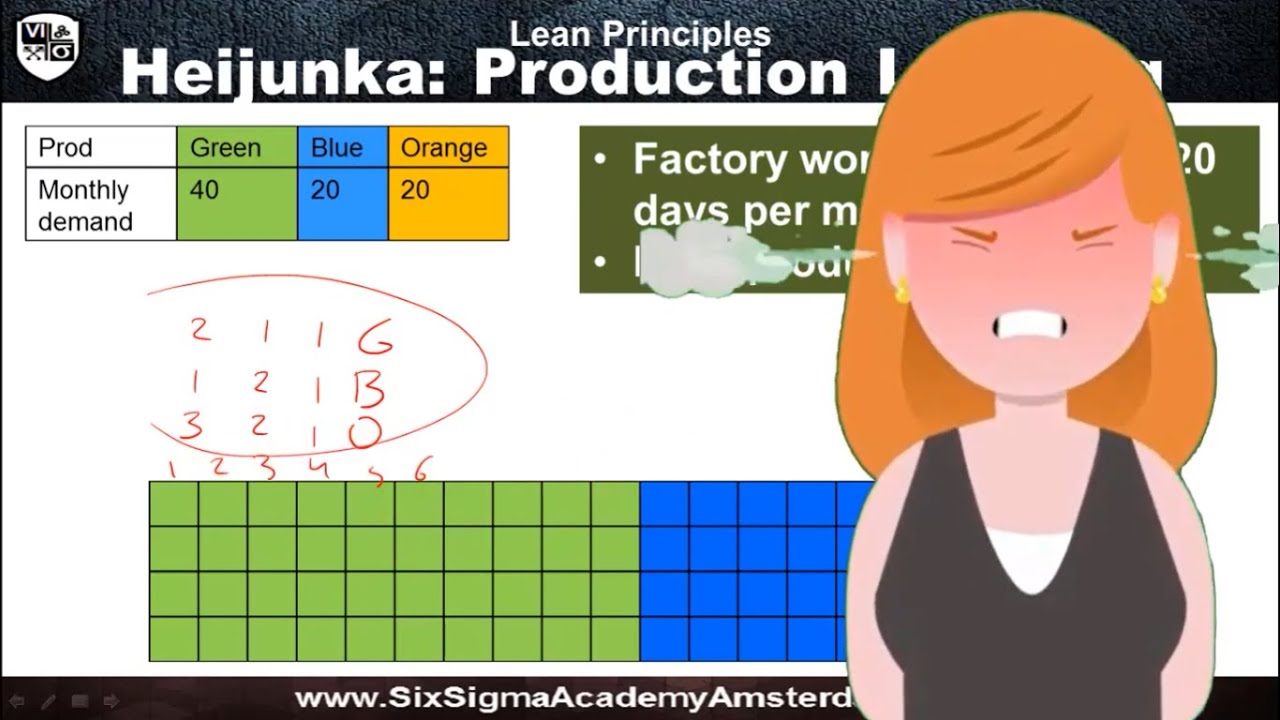

How to Use the Just In Time Method in Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It's the process of obtaining the right amount and timing of resources when you need them. This means that you only pay for what you actually use. Frederick Taylor, a 1900s foreman, first coined the term. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT is about planning ahead. You should have all the necessary resources ready to go so that you don’t waste money. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. This way you won't be spending more on things that aren’t really needed.

There are many JIT methods.

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will allow you to track how much material you have left over after using it. This will allow you to calculate how long it will take to make more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows one to predict how much they will sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT: This is the most popular form of JIT. Here you can allocate certain resources based purely on demand. You will, for example, assign more staff to deal with large orders. If there aren't many orders, you will assign fewer people.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based: This is very similar to cost-based but instead of looking at total costs of the company you are concerned with how many raw materials you use on an average.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT: This is the latest form of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. This is used to increase production and minimize inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It's important as it reduces leadtimes and increases throughput.