Manufacturing engineers are responsible for converting raw materials into new and updated products, creating efficient systems that integrate production processes and overseeing people involved in product manufacturing. This career is rewarding and can provide a great work-life balance.

The average manufacturing engineer salary in the US is $77,500. This figure was derived from data collected by 655 TurboTax customers who identified themselves as manufacturing engineers. It includes taxable wages and bonuses.

What is the Manufacturing Engineering Salary?

The manufacturing engineering salary ranges from $28,500 to $178,500 depending on the education, skills, experience, employer & location. Those who have experience in the industry tend to make more than those without it, whereas those who are just starting out typically earn less.

Salary of Entry-Level Manufacturing Engineer: The average salary for a manufacturing engineer at the entry-level is $52,000. This amount varies from state to state. It's best to check the average salary in your area prior to applying for a position.

What are the qualifications for becoming a manufacturing engineer?

In most cases, you need at least a Bachelor of Science in the relevant field. It could be any of the engineering specialties available or something more general, like computer science. However, it's best to have a graduate degree if you want to advance in the field or conduct research.

What is the typical manufacturing engineer's job?

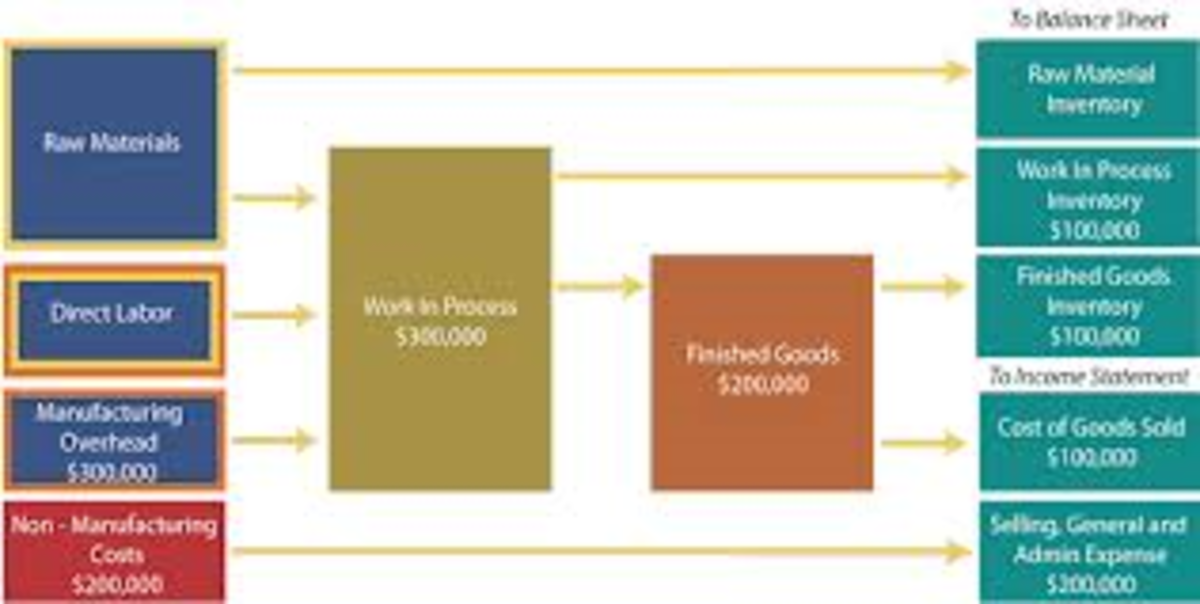

Engineers are often responsible for designing and developing systems that increase productivity at work. They are experts at creating the processes which turn raw materials in to a finished product while focusing on eliminating wastage. The engineers have excellent problem-solving capabilities that help them identify and solve issues quickly, whether they are developing new products for the market or upgrading current ones.

What are the duties of a manufacturing engineer?

The main responsibilities of a manufacturing engineer include keeping projects on track and on budget, ensuring that production is efficient and maintaining high quality. They must have the ability to communicate effectively with technicians, design engineers and management. They also need to understand the impact of their decisions on production costs and timelines and how they can manage these factors for the benefit of all project members.

What qualifications are required to become an industrial and manufacturing engineer?

A manufacturing engineer can be needed by any company who has its own in-house manufacturing. This can include multinational corporations, small businesses, research and development laboratories or local companies who produce a variety of products from food to pharmaceuticals.

Manufacturing engineers can be found in many different industries. They include aerospace, defense software, hardware development, robots, and assembly-line automation. Manufacturing engineers may work from an office, a lab or a factory.

What is the average salary of a manufacturing engineer?

In the US, manufacturing engineers earn between $57.839 and $86,809 a year. This figure is calculated using data from TurboTax Users who have reported their occupation of manufacturing engineer. It includes tips, bonuses, taxable wage, and more.

FAQ

Why is logistics important in manufacturing?

Logistics are essential to any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics play a key role in reducing expenses and increasing efficiency.

What skills should a production planner have?

Being a production planner is not easy. You need to be organized and flexible. You must also be able to communicate effectively with clients and colleagues.

How can efficiency in manufacturing be improved?

The first step is to determine the key factors that impact production time. The next step is to identify the most important factors that affect production time. You can start by identifying the most important factors that impact production time. Once you've identified them all, find solutions to each one.

What are the essential elements of running a logistics firm?

It takes a lot of skills and knowledge to run a successful logistics business. You must have good communication skills to interact effectively with your clients and suppliers. You must be able analyze data and draw out conclusions. You need to be able work under pressure and manage stressful situations. To increase efficiency and creativity, you need to be creative. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

It is important to be organized and efficient in order to meet tight deadlines.

Are there ways to automate parts of manufacturing?

Yes! Yes. Automation has been around since ancient time. The wheel was invented by the Egyptians thousands of years ago. Robots are now used to assist us in assembly lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Automated assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation could also be used to improve manufacturing. 3D printing, for example, allows us to create custom products without waiting for them to be made.

How does a production planner differ from a project manager?

The difference between a product planner and project manager is that a planer is typically the one who organizes and plans the entire project. A production planner, however, is mostly involved in the planning stages.

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document ensures that everything is prepared and available when you are ready for shooting. This document should also include information on how to get the best result on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to outline what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. For example, you might decide that you need a car but don't know exactly what model you want. To narrow your options, you can search online for available models.

Once you have found the right vehicle, you can think about adding accessories. What about additional seating? Or perhaps you need someone walking around the back of the car? Maybe you'd like to change the interior from black to a white color. These questions can help you decide the right look for your car. Another thing you can do is think about what type of shots are desired. What type of shots will you choose? Perhaps you want to show the engine or the steering wheel? These things will help you to identify the car that you are looking for.

Once you've determined the above, it is time to start creating a calendar. You can create a schedule that will outline when you must start and finish your shoots. You will need to know when you have to be there, what time you have to leave and when your return home. So everyone is clear about what they need to do. If you need to hire extra staff, you can make sure you book them in advance. There is no point in hiring someone who won't turn up because you didn't let him know.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects take only a few days while others can last several weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Shooting multiple takes over the same location will increase costs and take longer to complete. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budget setting is an important part of production planning. It is important to set a realistic budget so you can work within your budget. You can always lower the budget if you encounter unexpected problems. However, you shouldn't overestimate the amount of money you will spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing can be found in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Lean manufacturing includes five basic principles:

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three types of lean manufacturing.

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.