It is easy to find a job within the Dallas logistics industry, especially if your search is well-researched. You can find jobs in a wide variety of industries, including shipping, trucking, and logistics. All levels of employment are available, including executive and entry-level roles. Free advice is also available from human resources professionals.

Dallas is home to a growing logistics industry. The benefits package and pay are excellent from the very beginning. Some jobs that pay well include benefits like medical insurance and memberships to the gym. If you are a recent grad looking for your first job, you may want to consider a position as a courier. You can also opt for a position as a driver. You can expect five shifts per work week.

If you have a driver’s license, good credit scores, and a track record of accomplishments, you will be able to get a logistics job in Dallas. You may be eligible to receive a free driver's training course at your community college. There may be an opportunity to join the military preferred hiring programme.

There are many exciting jobs in the logistics industry that require a variety of skills. A job as a driver, transport service specialist or courier can be found. A warehouse manager, supply chain analyst or executive assistant are possible positions. You will have many responsibilities as a job holder. However, your most important task will be to coordinate key activities in your organization. As a logistics professional, you can implement the best strategies to ensure that goods move smoothly. You can find work in the logistics sector, which is a growing industry in Dallas. No matter if you're looking to become a courier or truck driver, there are many local companies that can offer you the right job. You can get your foot in to the trucking industry by applying for a job. Apply online if there is a position that interests you. There are a number of job portals that allow you to browse and apply for jobs in Dallas. Online job listings are also available for free to view what companies are seeking.

The logistics industry is filled with exciting opportunities, from truck driver to logistics manager to executive assistant. A variety of job websites can help you find the best jobs in Dallas. You may also want to check out CareerOneStop's free online job site to see what companies are looking for in your area. The best thing about this site is that you can receive free advice from human resources professionals.

FAQ

What are the 7 Rs of logistics?

The acronym 7R's for Logistics stands to represent the seven basic principles in logistics management. It was developed by the International Association of Business Logisticians (IABL) and published in 2004 as part of its "Seven Principles of Logistics Management" series.

The following letters make up the acronym:

-

Responsible – ensure that all actions are legal and don't cause harm to anyone else.

-

Reliable – have faith in your ability and capability to keep promises.

-

Use resources effectively and sparingly.

-

Realistic - Take into consideration all aspects of operations including cost-effectiveness, environmental impact, and other factors.

-

Respectful – Treat others fairly and equitably.

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable - provide customers with value-added services.

What are manufacturing and logistic?

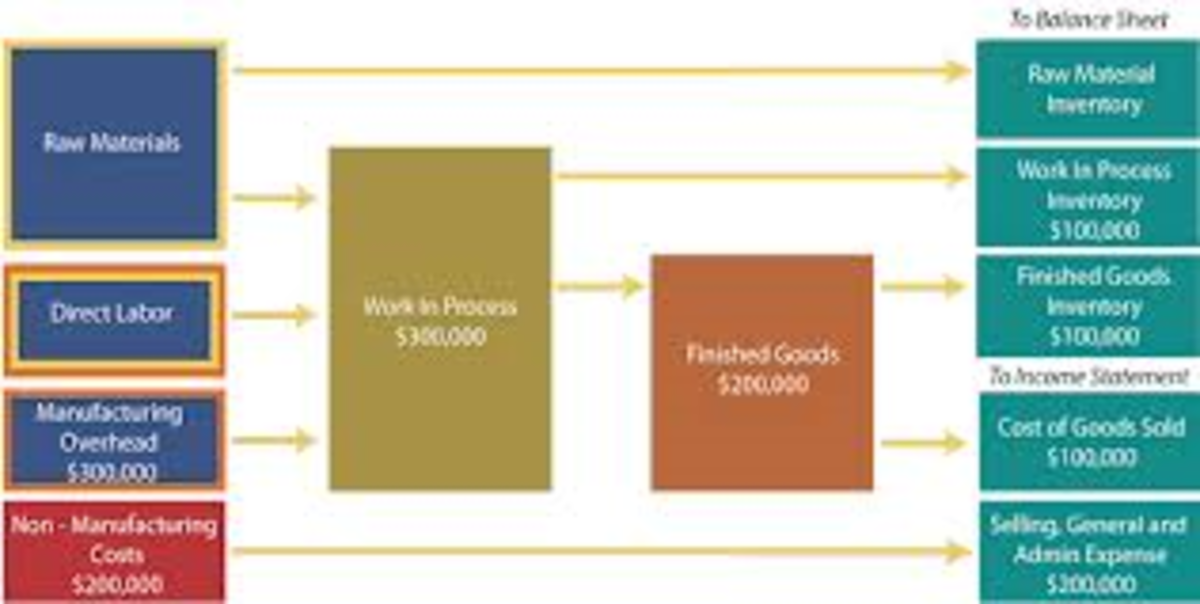

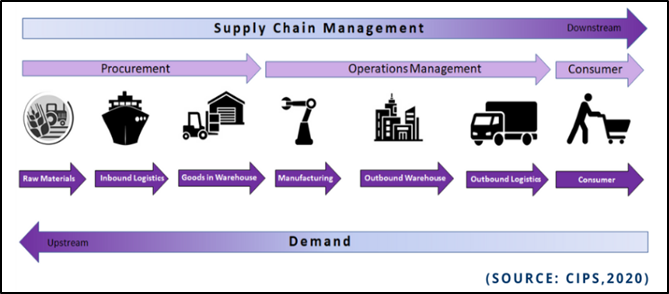

Manufacturing refers the process of producing goods from raw materials through machines and processes. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

How can manufacturing reduce production bottlenecks?

You can avoid bottlenecks in production by making sure that everything runs smoothly throughout the production cycle, from the moment you receive an order to the moment the product is shipped.

This includes planning to meet capacity requirements and quality control.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It emphasizes consistency and eliminating variance in your work.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing is widely used in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Lean manufacturing includes five basic principles:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. To increase their competitiveness, many businesses have turned to lean manufacturing. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

Any aspect of an enterprise can benefit from Lean manufacturing. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.