This article will cover the different types companies that are manufacturing in the U.S. The list will include industry trends as well as the costs involved in doing businesses in the U.S. Dun & Bradstreet can be a good resource for manufacturers because they collect information from a wide variety of reliable sources. This information is useful for manufacturers to assess their performance, growth potential and competitive pressures. This information is invaluable for any company looking to expand their operations.

The United States Manufacturing Companies List

The United States has 50 states, covering a large part of North America. The northwestern region of the United States includes Alaska and Hawaii, while New York City and Washington, DC are the major cities along the Atlantic coast. Los Angeles and Chicago, two of the most important cities in America, are both known for their iconic architecture and filmmaking. You will find many manufacturing companies in the United States. It is important to choose one that suits your needs.

It is important to include contacts at all levels in a list listing American manufacturing companies. This can include all contacts involved in every aspect of the operation. It should also contain contacts for marketing and sales development as well as purchasing and quality assurance. It is important not to forget that the list may have been updated.

Industry trends

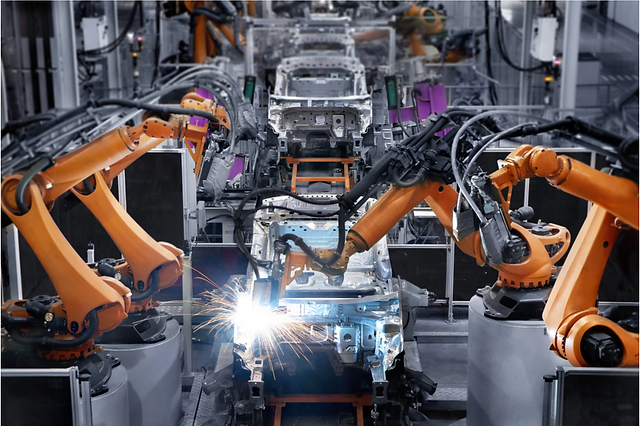

Manufacturers are becoming more concerned about rising labor and raw material costs as a result of the increasing global demand for goods. Some have chosen to reshoring while others seek to improve their ability to quickly switch production lines. With this in mind, some manufacturers are looking into automated production and other sustainable production practices. Here are some trends to keep your eye on. This article highlights three important trends for US manufacturers.

The U.S. industrial sector is a crucial indicator of the country's economic health. A rebound in manufacturing suggests that the economy is transitioning from recovery to extended growth. However, manufacturers still have to deal with a variety of issues, including labor and raw material challenges that are difficult in the past. Abhijit Shahide, BofA Securities Managing Director, discusses five major trends that will drive the manufacturing industry. The manufacturing industry is becoming more resilient in spite of technological advances.

Cost of doing business with the U.S.

The U.S. economic outlook is still positive, despite rising costs and tariffs. Many people predict that the world will enter recession in 2020. However, it is impossible to know when. In any event, in 2020, it is expected that the cost of doing American business will rise. This is good news to American businesses but also presents risks for newcomers.

The cost of labor and raw material may not seem that significant but you cannot avoid registration costs and startup expenses. These expenses can have a negative impact on your business' profitability. However, you can reduce your overall costs to keep your business moving. Look for cost-saving options if you can't reduce these expenses. Consider leasing or hiring equipment, or find more efficient ways to use your existing resources.

FAQ

How can excess manufacturing production be reduced?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. We could use these resources to do other productive tasks.

Kanban systems are one way to achieve this. A Kanban board can be used to monitor work progress. Work items are moved through various states to reach their destination in a Kanban system. Each state represents a different priority.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. If a task is still in its beginning stages, it will continue to be so until it reaches the end.

This keeps work moving and ensures no work is lost. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Waste includes anything that does not add value to the product. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

These ideas will help manufacturers increase efficiency and lower costs.

What is the responsibility of a production planner?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They make sure that the product and services meet client expectations.

What skills is required for a production planner?

Being a production planner is not easy. You need to be organized and flexible. It is also important to be able communicate with colleagues and clients.

What are manufacturing & logistics?

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Manufacturing and logistics can often be grouped together to describe a larger term that covers both the creation of products, and the delivery of them to customers.

How can we improve manufacturing efficiency?

The first step is to identify the most important factors affecting production time. We then need to figure out how to improve these variables. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you have identified them, it is time to identify solutions.

What are the four types in manufacturing?

Manufacturing is the process that transforms raw materials into useful products. It involves many different activities such as designing, building, testing, packaging, shipping, selling, servicing, etc.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands for "Sort", 'Set In Order", 'Standardize', & Separate>. Toyota Motor Corporation invented the 5S strategy in 1954. This methodology helps companies improve their work environment to increase efficiency.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. Cleaning, sorting and packing are all done daily. These actions allow workers to perform their job more efficiently, knowing what to expect.

Implementing 5S requires five steps. These are Sort, Set In Order, Standardize. Separate. And Store. Each step is a different action that leads to greater efficiency. Sorting things makes it easier to find them later. When you set items in an order, you put items together. Once you have separated your inventory into groups and organized them, you will store these groups in easily accessible containers. Finally, label all containers correctly.

Employees must be able to critically examine their work practices. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. In order to use the 5S system effectively, they must be able to learn new skills.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.