The best books on lean manufacturing offer industry leaders essential guidance. They are written in plain English and provide clear explanations. The bestselling book discusses a variety concepts, such as improving business processes, reducing expenses, and improving quality. Implementation is simple thanks to the detailed drawings and step by step instructions. The book also includes information about the many different tools available for lean manufacturing.

The book provides a comprehensive overview of Toyota's global success and the Toyota production system. It also describes Toyota's motivation, problem solving and management style. It also explains Toyota's Lean strategy, and the 14 management principles which are the core of its business practices. A chapter is also included on the automotive industry. This includes a section about how Toyota used lean principles to improve the automotive sector.

Lean manufacturing is a manufacturing process that aims to improve the quality of the products and services that a company produces. It eliminates waste to make the manufacturing process more efficient and less error-prone. The most successful manufacturing processes involve the interactions of highly skilled people and machines. These interactions account for the majority of a manufacturing company's costs.

The Lean Manufacturing Tool Book (the best book on lean manufacturing), The Toyota Way 14 Management Principles For Improving Quality And Productivity, The Machine That Changed the World: How Toyota Created a Competitive Advantage are some of the best books. These books cover the Toyota production system in detail and offer practical tips and steps for applying Lean techniques in any manufacturing setting. Lean Manufacturing Tool Book is a comprehensive guide to the tools and techniques used in Lean manufacturing. It provides expert advice and a list of the various tools available. The book includes information on Lean manufacturing concepts including Six Sigma, and Lean problem solving.

The Toyota Way was one of the first books to introduce Lean manufacturing. It covers Toyota's management principles, and how to apply them in your own company. It also contains information about the organizations that make up Toyota's success, and the philosophies they use. It also features a new afterword that discusses Lean's effects on the manufacturing business since the publication. It also contains updated frameworks that can be used to improve production, reduce costs, and improve quality.

The Machine that Changed the World - How Lean Changed the World - This book was the first to fully explain the Toyota Production System, and the impact it had on the manufacturing industry. It was published in 1990. It provides an overview of the system and gives the reader an important context for the role of Lean in the manufacturing industry since the book's publication. It includes a new afterword and a revised foreword that provide a better understanding of the Toyota Production System and its impact on the global manufacturing industry. It also provides an explanation of the fundamental ideas behind all Lean practices.

The Toyota Kata Flow-Focused Manufacturing Methodology: Another important book. It describes how Toyota works closely with customers to deliver quality products and services. It explains Toyota's commitment towards quality, problem-solving, speeding up business operations and ensuring customer satisfaction. It also explains how Toyota selects and hires employees and how they are motivated to deliver high quality products and services.

FAQ

What skills is required for a production planner?

You must be flexible and organized to become a productive production planner. Effective communication with clients and colleagues is essential.

What is the responsibility of a manufacturing manager?

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They should be aware of any issues within the company and respond accordingly.

They should also know how to communicate with other departments such as sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

What does manufacturing mean?

Manufacturing Industries is a group of businesses that produce goods for sale. These products are sold to consumers. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. They manufacture goods from raw materials using machines and other equipment. This includes all types if manufactured goods.

Statistics

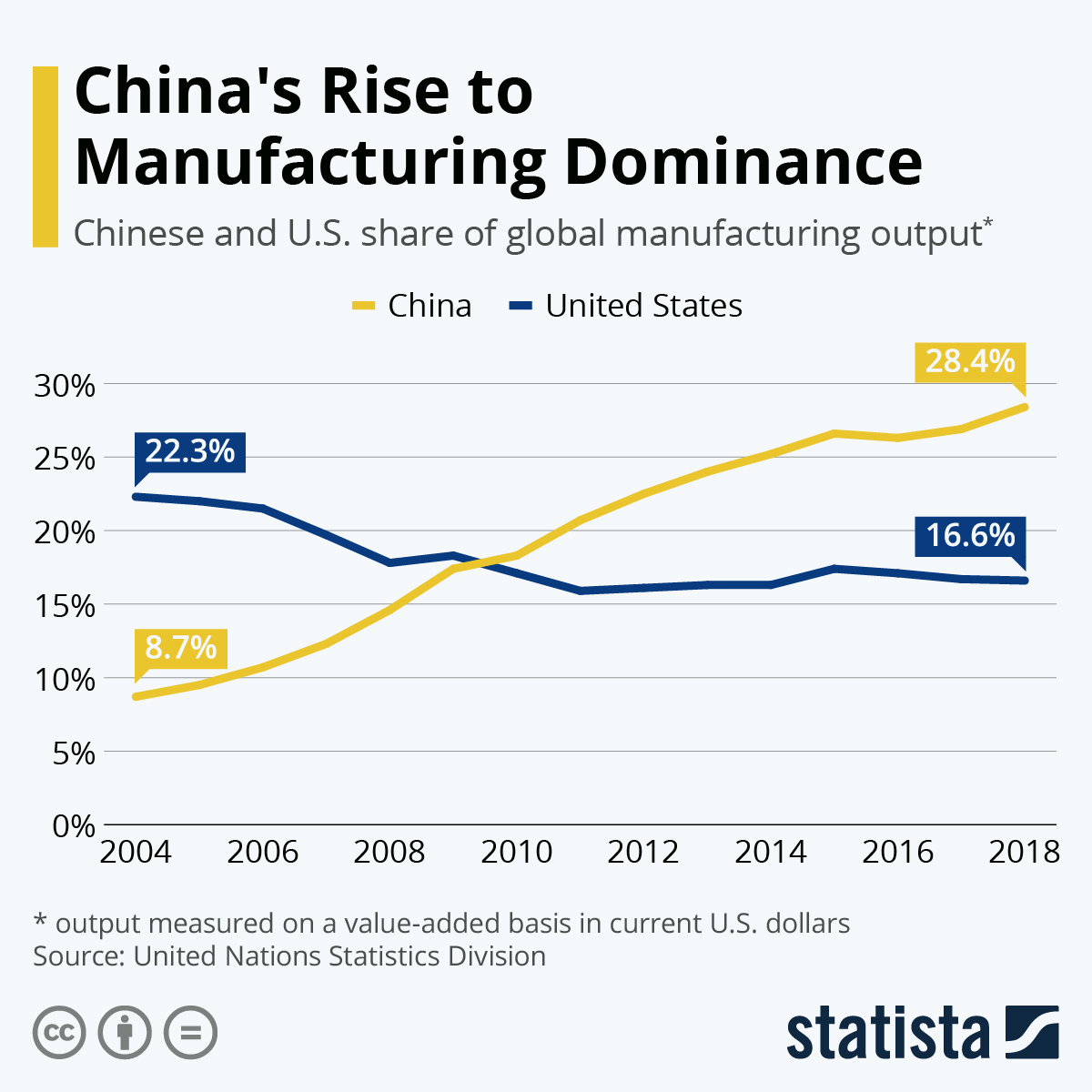

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use 5S to Increase Productivity in Manufacturing

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. Cleaning, sorting and packing are all done daily. Workers can be more productive by knowing what to expect.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step has a different action and leads to higher efficiency. If you sort items, it makes them easier to find later. When you set items in an order, you put items together. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. Finally, when you label your containers, you ensure everything is labeled correctly.

Employees must be able to critically examine their work practices. Employees should understand why they do the tasks they do, and then decide if there are better ways to accomplish them. They will need to develop new skills and techniques in order for the 5S system to be implemented.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They feel more motivated to work towards achieving greater efficiency as they see the results.