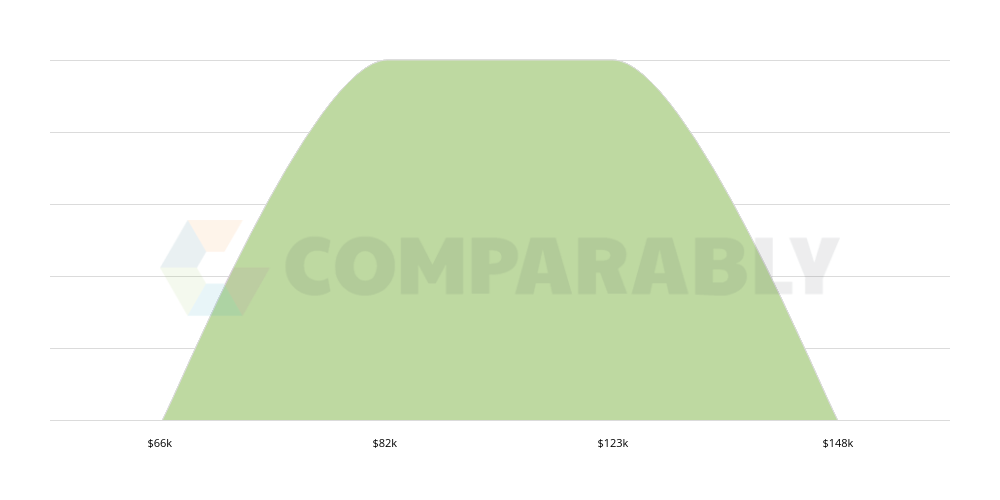

A manufacturing job in the Capital Region of Texas is more than just a job. These jobs require an advanced education and training in order to reap the benefits of the industry. The area's median annual salary is $88,406 for a manufacturing worker. Wages are expected to increase by 2.5% in the future. A number of manufacturing companies have adopted a number of safeguards to prevent workers from becoming susceptible to health and safety issues.

In fact, the Capital Region of Texas is home to 30 percent of the state's manufacturing jobs. The sector's workers declined by -800 in Feb 2021 but this was no sign of a reduction. Acme Brick, Samsung Austin Semiconductor and Acme Brick are just a few of the innovative companies that can be found in this area. This is why the metropolitanplex is one reason that it is so vibrant.

Texas Commission on Economic Opportunity, (TCEO), created a new interactive exhibition to showcase the Capital Region's remarkable manufacturing industry. It has a chart showing the area's manufacturing industries, as well a lot of useful information. The most notable feature is the "Essential Texas", a mobile app that allows visitors to access data about local businesses, tourism and the history of the area. A virtual visitor’s center is another great feature. You can learn about the regions most important industries as well as how they benefit the local community.

The interactive exhibit is definitely impressive. However, you'll also want to look at other TCEO resource. The Capital Region of Texas provides an overview of a large area of Texas that stretches from Llano all the way to San Marcos. Here you can see how the region has managed a recovery from the recession and how it is able continue to grow with new industries. A large number of highly qualified and skilled candidates make the region a great location to begin a new career. You have many options, whether you're looking for a part-time or full-time job.

It is home to several of the most well-known companies in the technology sector, including Apple, Dell, Oracle. The capital city also houses Rhythm Superfoods - a natural and organic snack company. Manufacturing is exciting and diverse in the Capital Region.

However, the capital city's manufacturing industry isn’t a monopoly. Despite the aforementioned recession, the area has maintained a robust employment base, which has resulted in more than 65,000 manufacturing jobs in the region alone. These jobs are not cheap, and the country's manufacturing achievements surpass them all.

FAQ

How can efficiency in manufacturing be improved?

The first step is to identify the most important factors affecting production time. The next step is to identify the most important factors that affect production time. You can start by identifying the most important factors that impact production time. Once you identify them, look for solutions.

Why is logistics important in manufacturing?

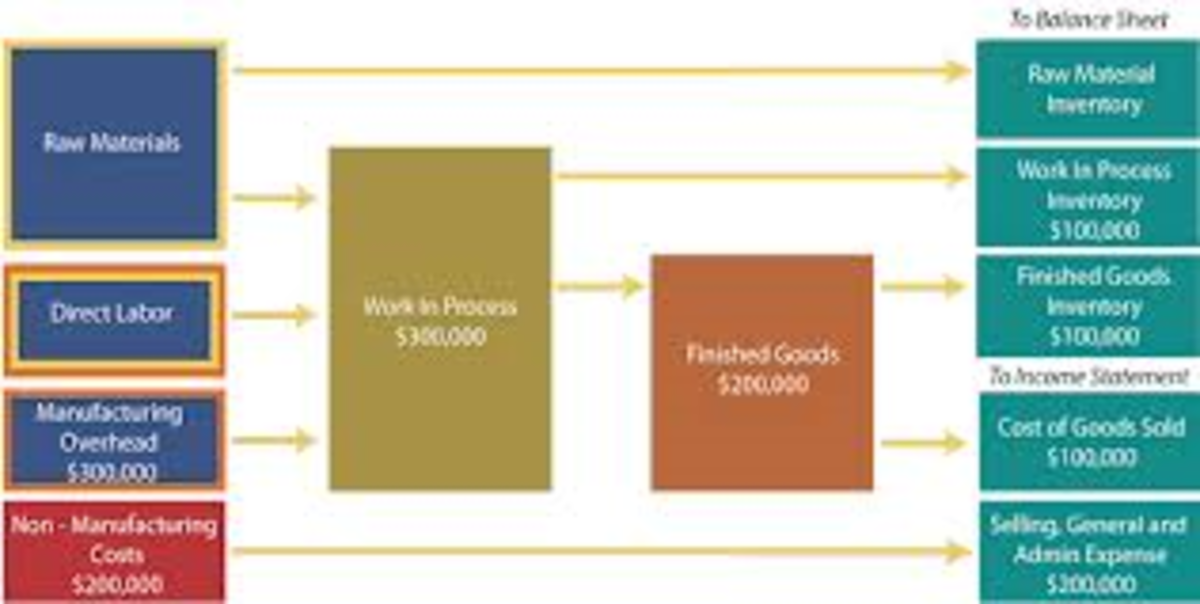

Logistics is an integral part of every business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

What are the logistics products?

Logistics refers to all activities that involve moving goods from A to B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

What are the essential elements of running a logistics firm?

It takes a lot of skills and knowledge to run a successful logistics business. You must have good communication skills to interact effectively with your clients and suppliers. You will need to know how to interpret data and draw conclusions. You need to be able work under pressure and manage stressful situations. You must be creative and innovative to develop new ideas to improve efficiency. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

You must be organized to meet tight deadlines.

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP), or production planning, is the process by which you determine what products are needed at any given time. Forecasting demand is one way to do this.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

What does manufacturing mean?

Manufacturing Industries are companies that manufacture products. These products are sold to consumers. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They make goods from raw materials with machines and other equipment. This includes all types if manufactured goods.

How can manufacturing overproduction be reduced?

Improved inventory management is the key to reducing overproduction. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. This could help us free up our time for other productive tasks.

Kanban systems are one way to achieve this. A Kanban Board is a visual display that tracks work progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents an individual priority level.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This helps to keep work moving forward while ensuring that no work is left behind. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This allows them to adjust their workflows based on real-time information.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does nothing to add value to a product is waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Material surplus

By implementing these ideas, manufacturers can improve efficiency and cut costs.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Lean manufacturing can be found in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types of lean manufacturing:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT means that components are assembled at the time of use and not manufactured in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.